CHORITAB IN DENTAL CLINICS

Biofilm and Pathogen control in the water pipeline

The Aerosols generated during the operative procedures can be a

cause of infection, and viral contamination. Hence it is necessary

to eliminate the pathogens in the water line and the during operative

procedures

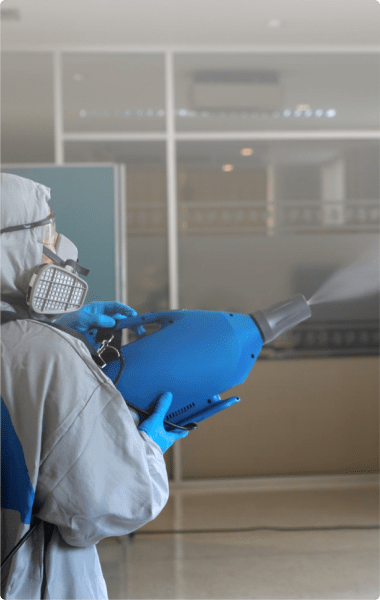

Surface Sanitization

1. 1g – CHLORITAB – can produce 500 ml liquid of disinfectant. This is effectively used for wiping, spraying.

2. 10 g – CHLORITAB – can produce 10 litre of disinfectant.

This is effectively used for mopping, internal and external hard floor surface.

3. 20 g – CHLORITAB – take 500 ml of plastic bowl and add 1 tablet of 20 g, Keep it overnight. Small Aerator can be used for faster release.

Air Quality Control: Odor & Purity

1. Purifies any room as it is applicable for all types of indoor air fumigation.

2. One CHLORONE sachet can treat upto 400-450 sq ft of area.

3. Reaches every niche and corner of the room.

4. No personal or technical assistance needed.

5. Eliminates the need for any machine.

6. Highly economical and low cost product.

7. Human friendly.

Surface Disinfection

1. 1g – CHLORITAB – can produce 500 ml liquid of disinfectant. This is effectively used for wiping, spraying.

2. 10 g – CHLORITAB – can produce 10 litre of disinfectant.

This is effectively used for mopping, internal and external hard floor surface.

3. 20 g – CHLORITAB – take 500 ml of plastic bowl and add 1 tablet of 20 g, Keep it overnight. Small Aerator can be used for faster release.

POULTRY MEAT PROCESSING

Packaged meat sanitation before final packing is a very complicated process, due to presence of very high organic load, fats, oil and grease. And resultant microbial load inside the packaged food is directly dependant on the product shelf life. And a goods bio-security measure can help in increasing the product shelf life and reduce the product obsoletion. Some of the in process applications are.

- During broiler defeathering.

- Maintenance of a low residual in the scalding tank (0.5ppm).

- Carcass Sprays

- Spin chillers

Fish & Seafood Processing

Sea food collection and processing is a very complex process due to presence of very high organic load, fats, oil and grease. A better bio-security procedure and protocol is directly proportional to the resultant product quality and obsoletion. And a goods bio-security measure can help in increasing the product shelf life and reduce the product obsoletion. Some of the in process applications are.

- Dipping of descaled fishes and deheaded shrimps.

- Ice preparation for the catch storage.

- Display and storage cabinet sanitation

- Final product rinse before freezing and packing.

- Fish and egg transportation.

FRUITS AND VEGETABLE WASHING Post harvest –

CDD 5000/CHLORITAB with its versatile nature is widely used in the post harvest pre-treatment, before the crop is repacked or reprocessed. Some of the most common process can be – Pulp and Juice production, Raw food packaging for direct sales, Raw crop for direct use in food productions.

- Spraying on the Post harvest crop for Microbial control.

- Dipping and cleaning in Dump tank for yeast and mold control.

- Salmonella control in fresh cut packaged fruits.

- Prevention and reduction of microbial induced deterioration and obsoletion.

Milk and Dairy Product processing –

Being a 24 hr process, milk processing is very susceptible to microbial contamination. Poor sanitation of food contact surface are responsible for outbreaks of food borne diseases. Inadequate surface sanitation and rapid soil building shapes ideal condition for biofilm formation. Common applications areas are as follows.

- Equipment sanitation during or post CIP cycle.

- Filling machines, filling heads, conveyors and other equipment surface sanitation.

- Process water pre-treatment.

- Ice-cream, Cheese and Paneer production.

Drinking water treatment with ClO2 –

Being a Pioneer in Chlorine Dioxide manufacturing in India. We are India’s only established & approved manufacturer for our various range of ClO2 products. ( Powder, Liquid, Tablets) etc… We have a CGMP certified production facility spread over 20000 Sq. feet. Our facility & product both are as per ISO 9001-2015 certification. And they are following the quality norms as per NSF – ANSI 60 standard.

Our products are approved by Ministry of drinking water and Sanitation in India.

Our products are approved/used in over 13 states in India for drinking water & exported in over 23 countries globally. Some of the proposed applications are as follows.

- Drinking water disinfection in surface water.

- Boosting stations – Tertiary disinfection of Drinking water.

- Tube well and Borewell water treatment.

- Sequential dosing for Colour and Odour treatment.

- Aesthetic treatment for Algae removal and taste improvement.

Waste Water Treatment

Due to lower oxidation potential, Chlorine dioxide does not form- THM’s ( Trihalomethane ) and other disinfection bi-products which are carcinogenic in nature, which makes it an ideal biocide in waste water treatment. CDD 5000 has following advantages over the conventional process in tertiary waste water treatment.

- Does not react with Ammonia, hence no chloramine formation.

- Does not react with Organics, hence no formation of carcinogenic substances.

- Improves colour and reduces odour from waste water.

- Removes biofilm from all the contact parts, tanks, pipes and pumps, which is very sever due to high nutrient load.

- Reduced BOD and COD in the waste water.

Beverage Production ( Alcoholic/Non Alcoholic)

A brewery process presents one of the biggest challenges possible to a microbiological control program. Microorganisms are responsible for both the production and the degradation of the product. Microbial control is also critical for production and filling equipment. CDD 5000 offers following applications.

- Process water sanitation.

- Waste water treatment.

- Yeast and Yeast slurry treatment.

- Equipment sanitation

- Bottle washing and sanitation.

Microbrewery & Winery Production

Wine Production –

In recent years, CDD 5000 has been introduced to sterilize containers in the food industry and during wine production. Bacteria, yeast, molds and spoilage microorganisms are the enemies of fine wine product. Unfortunately many antimicrobial products generate TCA/TCP residuals which also affect finished product. Now, with the help of powered method of generating ClO₂ with superior antimicrobial abilities of the product can be utilized with absolutely no byproducts.

Dairy Farming –

In the dairy industry there is a direct correlation between the amount of water consumed by cows and the resulting amount of milk they produce on a daily basis. Also the quality of milk produced ( SCC – somatic cell counts ) is also dependant on the quality of water consumed. CHLORITAB has wide application in dairy farming industry.

- Calving Pen cleaning.

- Drinking water troughs and tanks.

- Milking equipment’s and machinery.

Poultry Drinking Water

Poultry – Breeder and Broiler Farms. –

CHRLORITAB has a very good effectiveness against most commonly known water borne pathogens like Ecoli, Salmonella, Staphylococcus etc… As the performance is independent of pH range ( 4-10), and ability to remove biofilm from the pipeline and other instruments, makes – CHLORITAB an ideal biocide for Breeder and Broiler farms. Some of the advantages are

- Improved feed conversion rate.

- Improved disease control.

- Lower Mortality rate.

- Improved bird performance.

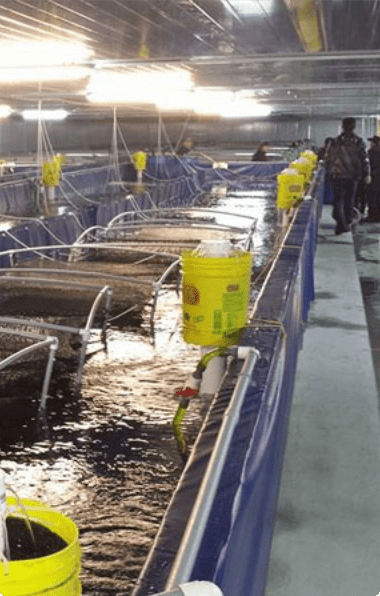

Aquaculture – Shrimp/Fish Breeding.

CHLORITAB is the only oxidising biocide – used in presence of shrimp/fish in the pond. Its also used for all types of Fishes/Prawns – Herbivorous, carnivorous and also Vannamei ( King Prawn ) and Black tiger Prawn. Being a selective oxidizer CHLORITAB, reduces Anaerobic bacteria, virus and other pathogens. Following benefits can be expected with recommended usage

- Improves colour of water.

- Reduces green colony counts ( Vibrio count ).

- Neutralises organic waste.

- Reduces bacteriological load and also rate of regrowth.

- Prevents Pathogens from Developing resistance.

PHARMACEUTICAL INDUSTRY

Biofilms and the organisms thriving below the biofilms are the most common problems any high purity water system has. Due to phenomenon of immunity building biofilm develops inside the pipes, valves, vessels and impart biological load to water. CDD 5000 is most commonly used biocide in high purity water system with online dosing, with following applications.

- Process water/Raw water treatment.

- Cleaning in Place (CIP)

- Equipment sanitation.

- For Membrane & resin sanitation.

- Intermediate cleaning during production change overs.

- Sanitation of Raw & process water tanks.

UF Filtration Disinfection

Water is treated with reducing agents like Sodium metabisulfate, or sodium thiosulfate for removal of oxidative impurities which may damage the membrane Or the water is passed through activated carbon. Reducing agents are food to bacteria and carbon due to higher surface area are a safe haven for the pathogens to grow. This increases biological fouling inside membrane reducing the flow and output and imparting biological impurity to water.

- CDD 5000 with its unique ability can be used in presence of RO membrane.

- Improves membrane life.

- Improved output water quality and quantity.

- Reduces the CIP cycles and chemical consumption.

Greenhouse & Horticulture

Biofilm is a living complex of organic and inorganic complex which grows on irrigation tanks, recirculating tanks, pipelines, drippers, sprinklers etc… impacting the plant growth. Pathogens harbour withing the biofilms and transmit to the product during the attachment and detachment process.

- CDD 5000 is widely used in green house crop production with a constant residue in the treatment water.

- Dripper performance can be improved in outdoor nursery production with CDD 5000.

- Treat captured run-off for reuse.

- Improve the performance and increase plant output.

Hospitals, Maternity Homes, Clinics and Dentist –

Chlorine dioxide is an effective disinfectant capable of killing large number of water borne pathogens & bacteria’s including legionella, E coli, cryptosporidium, Giardia and others. The ability of chlorine dioxide to kill legionella is of great importance to hospitals, considering the risk of patient contacting legionnaires disease.

- For prevention of legionella in hot and cold water system.

- Indoor fumigations of rooms & operation theatres.

- For Instrument and Surface sanitation.

- Floors and other public area sanitation

- Ambulance fumigation.

- Bio Hazardous waste decontamination and neutralisation.