Material Compatibility & Dosing Setup for Chlorine Dioxide (CDD5000)

- Dosing Pumps (For Accurate Chemical Injection)

- Transfer Pumps (For Moving the Solution Safely)

- Piping Guidelines

- Tubing Requirements

- Hoses for Transfer

- Material Compatibility of Chlorine Dioxide (Important for Safety)

- Materials NOT suitable for undiluted chlorine dioxide

- Materials MOST compatible (Best Options)

- Diluted chlorine dioxide

- FAQs

Engage With Us

When working with chlorine dioxide systems like CDD 5000, choosing the right pumps, piping, and materials is very important. The correct setup ensures safe operation, accurate dosing, and long-term durability.

This guide explains—in a simple and user-friendly way—the recommended equipment and materials for dosing, transferring, and handling chlorine dioxide solutions.

- Dosing Pumps (For Accurate Chemical Injection)

- Transfer Pumps (For Moving the Solution Safely)

- Piping Guidelines

- Tubing Requirements

- Hoses for Transfer

- Material Compatibility of Chlorine Dioxide (Important for Safety)

- Materials NOT suitable for undiluted chlorine dioxide

- Materials MOST compatible (Best Options)

- Diluted chlorine dioxide

- FAQs

Engage With Us

Dosing Pumps (For Accurate Chemical Injection)

Dosing pumps deliver chlorine dioxide into the water stream. They can be:

- Solenoid-operated pumps

- Motor-driven pumps

The right type depends on the dosing rate and back pressure.

- Recommended Brands:

EMEC, Prominent, LMI, Pulsafeeder, Walchem.

- Material Requirements

All parts of the pump that touch the chemical must be made of:

- Kynar™

- PVC / CPVC

- Ceramic

Seals and O-rings should be:

- Viton™, Kalrez™, or Teflon™

- Control System

Your pump should support:

- Flow-meter control

OR - Time-based periodic injection

Make sure the pump includes an automatic bleed system to remove gases that form inside the pump head. This prevents “air binding.”

If you are unsure which model to choose — SVS AQUA can help you select the right pump for your plant.

Transfer Pumps (For Moving the Solution Safely)

Transfer pumps move chlorine dioxide from the storage tank to the dosing system. These should be:

- Motor-driven centrifugal pumps

- Magnetic drive type

Material Requirements

Wetted parts must be:

- Kynar™

- PVC

- CPVC

Seals/O-rings: Viton™, Kalrez™, or Teflon™

Pressure Limit

Maximum developed head:

- 20 psig or 45 ft. Head

Piping Guidelines

Use rigid PVC or CPVC pipes to carry out the solution.

Pressure Ratings

- Schedule 40: 5” Hg vacuum to 25 psig

- Schedule 80: Full vacuum to 25 psig

Installation Tips

- Use cemented joints wherever possible.

- Avoid flanged joints.

- Keep threaded joints to a minimum.

- Always seal threaded joints with Teflon™ tape (not liquid Teflon).

- For long distances or when passing through walls, use double-walled piping for safety.

Tubing Requirements

For dosing tubing:

- Use flexible Kynar™ tubing

- Fittings should be Kynar™ compression type

Keep tubing running short.

To protect against UV light (from sunlight or indoor lighting):

- Wrap tubing in tape

OR - Place it inside a larger opaque tube (like black polypropylene)

Hoses for Transfer

- Use PVC transfer hoses

- Can be reinforced or non-reinforced

- Must be vacuum rated

- Minimum size: ¾ inch

Hose connections should be multi-barb type made from:

- PVC

- CPVC

- Kynar™

- Glass-reinforced polypropylene

Always seal threaded joints with Teflon™ tape.

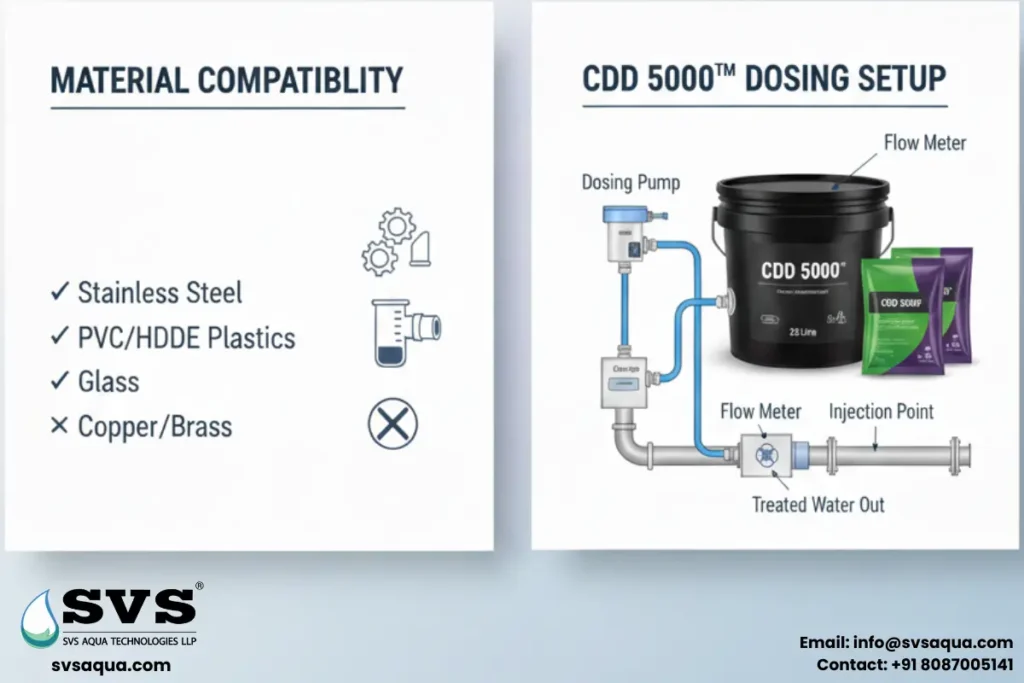

Material Compatibility of Chlorine Dioxide (Important for Safety)

Chlorine dioxide—especially in high concentration—is corrosive to many metals and plastics.

Materials NOT suitable for undiluted chlorine dioxide

- Aluminum

- Brass

- Bronze

- Carbon steel

- Stainless steel

- Copper

- Iron

- Zinc

Many plastics like PVC, CPVC, HDPE, and Polyethylene can weaken over time. Inspect these monthly if used.

Materials MOST compatible (Best Options)

- Fluoropolymers: Kynar™, Halar™

- Fluorinated elastomers: Viton™, Kalrez™, Teflon™

- Vinyl ester-FRP

Even these should be inspected monthly for stress cracks.

Diluted chlorine dioxide

- <50 ppm: Safe for most materials for up to 1 week

- <10 ppm: Generally safe for longer durations

Setting up the dosing and transfer system correctly is essential for:

- Safe handling of chlorine dioxide

- Preventing corrosion

- Ensuring accurate dosing

- Maintaining long equipment life

If you need help selecting pumps, piping, or materials for your chlorine dioxide system, SVS AQUA can assist you with professional recommendations.

FAQs

Kynar™, PVC, CPVC, and ceramic materials are the most compatible.

No. Stainless steel and most metals will corrode quickly when exposed to chlorine dioxide.

Solenoid or motor-driven dosing pumps from brands like EMEC, LMI, or Prominent.

Inspect all parts monthly for stress cracks, especially if using PVC or CPVC.

Yes, but only for diluted solutions, and it must be inspected regularly.

Must Read

AFM- Importance of Accreditation and Certification while selecting a filter media

Water Treatment Solutions

Life cycle analysis of AFM & Sand.

Water Disinfection & Hygiene