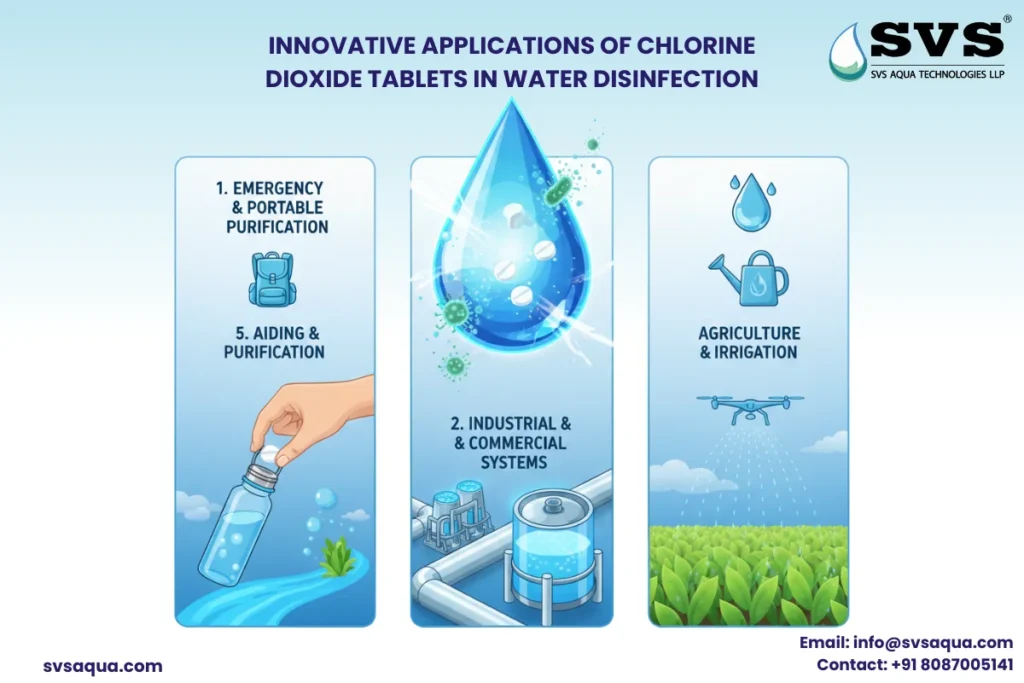

AFM with Rapid Gravity and Pressure Sand Filters

- Filtration & Polishing Process

- What Is Activated Filter Media (AFM)?

- AFM Properties and Benefits

- Why AFM Is Preferred Over Conventional Sand

- AFM vs Traditional Sand Filtration Media

- Material of Construction

- Particle Size and Uniformity

- Surface Charge and Adsorption Performance

- Biofouling Resistance and Self‑Sterilization

- Filtration Performance Efficiency

- Dual Functioning Advantage

- Why Choose AFM Filtration Systems from SVS Aqua

- FAQs

Engage With Us

FILTERATION & POLISHING PROCESS

Water from the pond is lifted using a pump and passed through a ZPM unit, followed by a Pressure Sand Filter (PSF). In this filtration stage, Activated Filter Media (AFM) is used instead of conventional sand to achieve superior filtration and polishing. AFM is specifically selected for wastewater and industrial water treatment due to its advanced filtration properties and long-term performance advantages.

- Filtration & Polishing Process

- What Is Activated Filter Media (AFM)?

- AFM Properties and Benefits

- Why AFM Is Preferred Over Conventional Sand

- AFM vs Traditional Sand Filtration Media

- Material of Construction

- Particle Size and Uniformity

- Surface Charge and Adsorption Performance

- Biofouling Resistance and Self‑Sterilization

- Filtration Performance Efficiency

- Dual Functioning Advantage

- Why Choose AFM Filtration Systems from SVS Aqua

- FAQs

Engage With Us

What Is Activated Filter Media (AFM)?

Activated Filter Media (AFM) is a high‑performance filtration media developed through more than 20 years of research and development by Dryden Aqua. It is designed as a replacement for traditional filter-grade sand.

AFM is manufactured from a specific type of recycled glass and processed to create a hydraulically optimised media with a controlled particle shape and size distribution. The media then undergoes an activation process that increases its surface area by nearly 300 times compared to sand or crushed glass. This activated surface carries a strong negative charge (zeta potential), enabling it to absorb organic matter, fine particles, and biological contaminants effectively.

AFM is the only activated glass filter media that is self-sterilising, thanks to permanent metal oxide catalysts on its surface that create a high redox potential.

AFM PROPERTIES & BENEFITS

- AFM is an activated amorphous alumino-silicate with a positive charge organic adsorption (OAD) number greater than 10, the activated hydrophilic surface has cation bridging, hydrogen bonding, and entropic interactions with organic molecules.

- High surface electrical charge density Zeta potential > -70mv as measured by kelvin probe analysis.

- Uniformity coefficient better than 1.5

- Sphericity factor better than 0.8

- AFM mechanically removes most particles down to 5 microns.

- Sand surface area, approx 3000m2/ton, AFM surface area >1,000,000 m2/ton

- The high surface negative charge potential helps to adsorb micron and sub-micron particles as well as some dissolved organics.

- AFM rejects bacteria growth and worm-hole channeling

- AFM is capable of very high turbidity loads up to 150 NTU.

- Back wash water requirement reduced by 50%.

- No requirement to replace AFM for the life of the filter.

- AFM removes heavy metals, Iron, Manganese & Arsenic from the water.

- AFM substantially reduces BOD,COD from water.

- AFM removes organic impurities/Natural organics matters from water.

- AFM removes color & odor.

- AFM removes Pseudomonas & Cyclops from water.

Why AFM Is Preferred Over Conventional Sand

Traditional sand filtration relies only on mechanical strain. Over time, sand surfaces wear down, develop biofilm, and suffer from channeling, which reduces filtration efficiency.

AFM, on the other hand, works through both mechanical filtration and mechanical adsorption, delivering consistent performance throughout the life of the media.

AFM vs Traditional Sand Filtration Media

| Feature | AFM | Sand |

|---|---|---|

| Surface Area | >1,000,000 m²/ton | ~3,000 m²/ton |

| Filtration Method | Mechanical + Adsorption | Mechanical only |

| Biofouling | Resistant | High |

| Particle Removal | Up to 5 microns | Limited |

| Backwash Water | 50% less | High |

| Media Life | 15+ years | Frequent replacement |

Material of Construction

Sand typically contains 50–60% silica, depending on its origin. AFM is produced from high‑quality waste glass with a silica content exceeding 70%, making it one of the toughest filtration materials available. This results in negligible abrasion loss and highly stable long‑term performance.

Impact:

- No reduction in media size

- Minimal top‑up requirement

- Consistent filtration efficiency for over 15 years

Particle Size and Uniformity

AFM Grade 1 media has a particle size range of 0.4 to 1.0 mm, compared to sand at 0.35 to 1.2 mm. With a uniformity coefficient of less than 1.3, AFM provides a highly uniform filtration bed.

Impact:

- No sand grading required

- Finer and more consistent filtration performance

Surface Charge and Adsorption Performance

AFM carries a strong negative surface charge of approximately –70 mV, enabling it to attract and absorb micron and sub‑micron particles, as well as dissolved organic compounds. Sand lacks surface charge and therefore cannot provide adsorption‑based filtration.

Impact:

- Stable and consistent filtration performance

- a No performance drop over time

Biofouling Resistance and Self‑Sterilization

AFM prevents biofouling through its activated surface, which generates free oxygen radicals in the presence of dissolved oxygen:

O₂ + H₂O → 3O⁻ + OH⁻

These oxygen radicals inhibit bacterial growth and prevent biofilm formation on the media surface. In contrast, sand rapidly develops bacterial coverage, leading to polysaccharide secretion, media coagulation, and wormhole channelling.

Impact:

- Sand filtration efficiency can drop by up to 50% within 6–9 months

- AFM maintains consistent performance throughout its lifespan

Filtration Performance Efficiency

AFM achieves:

- Up to 86% removal of 5‑micron particles

- Up to 91% removal of 10‑micron particles

This level of performance is comparable to disc, cartridge, or bag filters, while maintaining the simplicity and reliability of a media filter.

Dual Functioning Advantage

AFM uniquely combines mechanical sieving and adsorption in a single filtration stage. Unlike sand filters, which often require an additional activated carbon filter to remove colour, odour, and organic matter, AFM performs both functions simultaneously.

Impact:

- Eliminates the need for a separate carbon filtration stage

- Reduces system complexity and operational cost

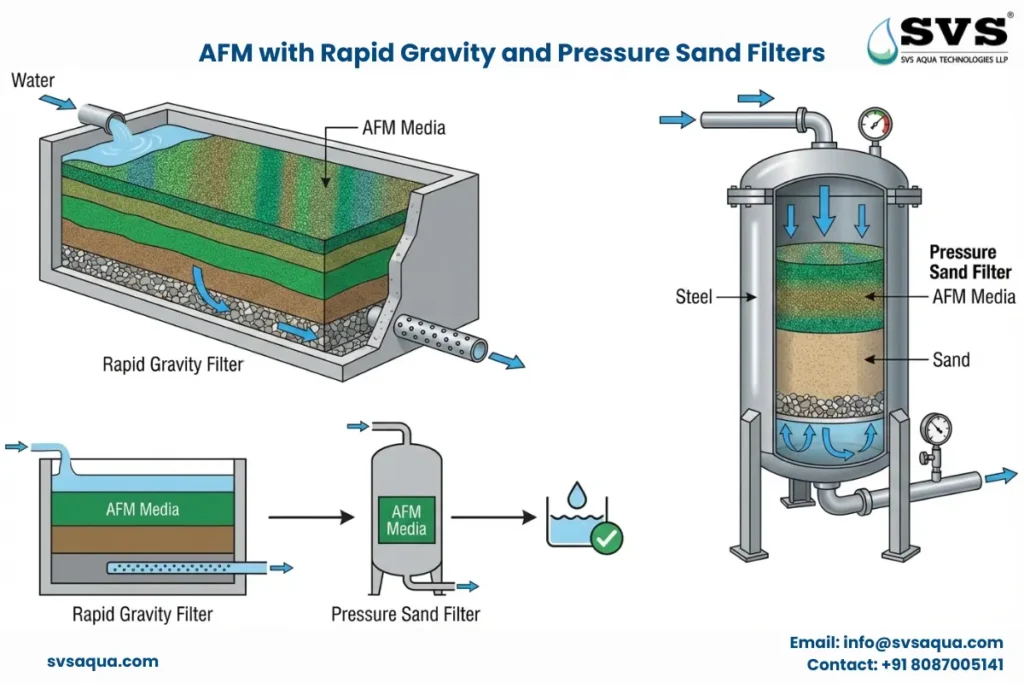

Why Choose AFM Filtration Systems from SVS Aqua

SVS Aqua offers advanced AFM‑based filtration solutions designed for drinking water, wastewater, and industrial applications. By integrating AFM into rapid gravity and pressure sand filters, we deliver superior water quality, reduced operating costs, and long‑term reliability.

Contact SVS Aqua to upgrade your filtration system with AFM and achieve consistent, high‑performance water treatment results.

FAQs

AFM not only mechanically traps dirt and particles; it also has a charged surface that helps attract and hold microscopic impurities. Because of this, it can filter finer particles and reduce things like organic matter, color, and even some heavy metals.

Yes. The special surface of AFM naturally resists bacterial growth. This means it stays cleaner longer and helps prevent biofilm and clogs that often happen with regular sand media.

No, AFM is very durable. It can last many years — often more than 10 years — without needing replacement, unlike regular sand which wears down and needs frequent change.

AFM can be used in both rapid gravity filters and pressure sand filters. These are common systems used for filtering water in ponds, industrial settings, and wastewater applications.

AFM provides better filtration performance, reduces backwash requirements, and offers long-lasting operation with less maintenance and better resistance to bacterial buildup

Must Read

Advanced cost optimization in drinking water treatment with activated filter media AFM by SVS Aqua

Water Treatment Solutions

Innovative Applications of Chlorine Dioxide Tablets in Water Disinfection

Chlorine Dioxide Applications