Chlorine Dioxide in Greenhouses & Nurseries: Technology Overview

Engage With Us

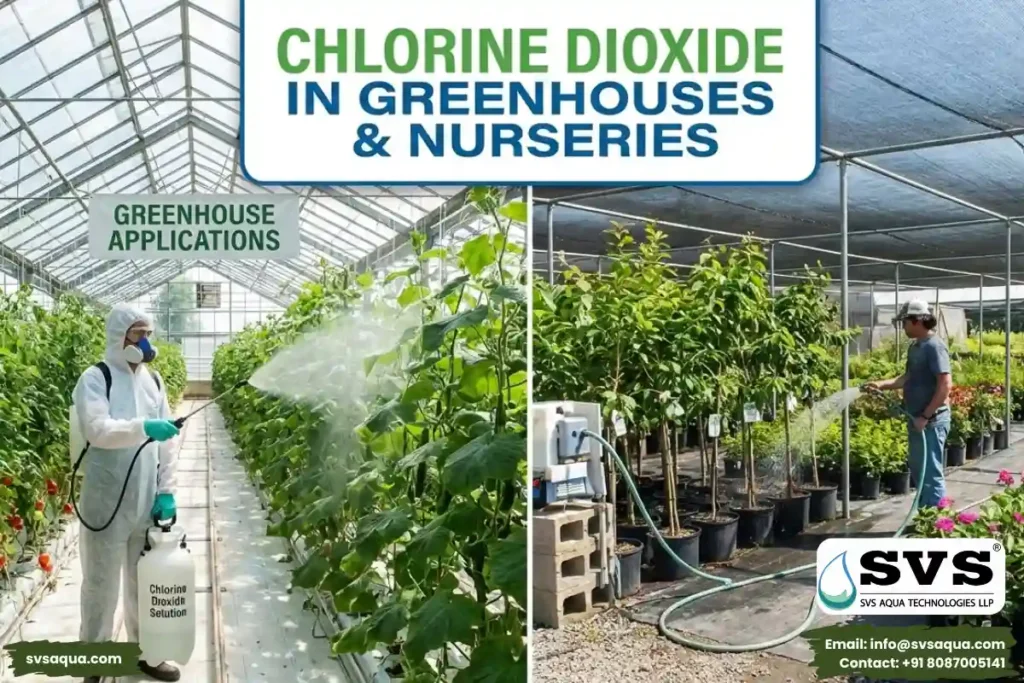

Greenhouses and nurseries face constant sanitation challenges—especially water treatment, biofilm removal, algae control and managing waterborne plant diseases. These challenges affect irrigation systems, crop quality, and overall plant health.

While several water treatment methods exist—such as chlorination, UV, copper, ozone, peroxide, and chlorine dioxide—only a few truly solve the sanitation issues found in horticulture.

This article explains why chlorine dioxide (CDD 5000) is one of the most effective solutions for growers.

Engage With Us

Understanding Biofilm: The Root Cause of Sanitation Problems

Biofilm is a sticky, slimy layer formed by microorganisms like bacteria and algae. It develops on surfaces that come in constant contact with water, such as:

- Irrigation lines

- Holding tanks

- Mixing tanks

- Recirculation pipes

- Fertiliser injection lines

In greenhouses and nurseries, biofilm grows faster because the fertiliser in the water acts like food for microbes. It becomes a strong, thick layer that:

- Blocks irrigation lines

- Hides and protects harmful pathogens

- Helps algae grow even in dark, underground pipes

- Reduces water flow and damages emitters

This is why many normal disinfectants cannot break through biofilm layers.

How Biofilm Grows — 3 Simple Stages

- Attachment

Microorganisms stick to the surface inside irrigation lines or tanks and begin multiplying. - Growth

The microbes produce a “protective glue” that blocks normal biocides from reaching them.

Only the top layer gets affected, while the deeper layers continue to grow. - Detachment

Pieces of biofilm break off and spread through the system, contaminating new areas.

This cycle continues until biofilm becomes a major system-wide problem.

Why Chlorine Dioxide (CDD 5000) Works Better

Chlorine dioxide is considered one of the strongest sanitation agents available today.

In horticulture, it is used by injecting it into irrigation lines or by adding tablets to water storage tanks.

Key advantages:

1. Works as a Gas in Water

Chlorine dioxide is a gas that dissolves in water.

Because of this, its molecules freely move around inside irrigation pipes and:

- Penetrate deep into biofilm layers

- Kill microbial colonies down to the surface where they are attached

- Prevent biofilm from re-forming

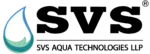

2. Easy to Use with CDD 5000

With CDD 5000 / Chloritab, growers can produce chlorine dioxide on-site.

The prepared stock solution is injected into irrigation lines at a recommended dose of 1 ppm, which can be reduced based on water quality.

3. Helps Control Algae, Pathogens, and Clogs

Chlorine dioxide not only removes biofilm but also:

- Prevents algae buildup

- Eliminates pathogens in the water

- Stops drip-emitter clogging

- Keeps tanks and troughs cleaner

Unconsumed gas naturally evaporates, so no extra rinsing is required for edible crops.

Real-World Results and Sustainability Impact

- Greenhouse Vegetable Production

Greenhouse growers using CDD 5000 report:

- Biofilm removal from irrigation lines

- Cleaner water troughs with less algae

- Fewer clogged drip emitters

- Cleaner post-harvest systems

- Safe sanitation without leaving harmful residues

- Outdoor Nursery Production

A nursery using recycled pond water had major issues with clogged emitters due to organic buildup.

After switching to chlorine dioxide:

- Biofilm and algae growth stopped

- Drip emitters stayed clean

- A full-time employee previously assigned to replace clogged emitters was no longer required

- Greenhouse Ornamental Production

Ornamental growers use chlorine dioxide to:

- Remove biofilm from tanks and lines

- Improve irrigation flow

- Treat water for disease prevention

- Sanitise recycled water before reuse

Biofilm and algae are key issues in modern greenhouse and nursery operations.

Chlorine dioxide (CDD 5000) offers a robust, dependable, and user-friendly solution that:

- Cleans irrigation systems

- Prevents obstructions

- Controls pathogens

- Improves overall sanitation

For growers trying to increase water quality and eliminate maintenance difficulties, chlorine dioxide is one of the greatest technologies available today.

FAQ FOR Chlorine Dioxide in Greenhouses & HORTICULTURE

CDD 5000 is used to clean irrigation lines, remove biofilm, control algae, and improve water quality in greenhouses and nurseries.

Chlorine dioxide works as a dissolved gas that penetrates deep inside biofilm layers and kills microbes at the root, preventing regrowth.

Yes, when used at recommended levels (like 1 ppm), it is safe and does not harm plants or leave harmful residues.

Yes. By removing biofilm and algae, it keeps emitters clean and prevents clogging, improving irrigation performance.

Yes, it is very effective in treating recycled water and helps maintain clean irrigation systems even in nurseries using pond water.

AFM- Importance of Accreditation and Certification while selecting a filter media

Water Treatment Solutions