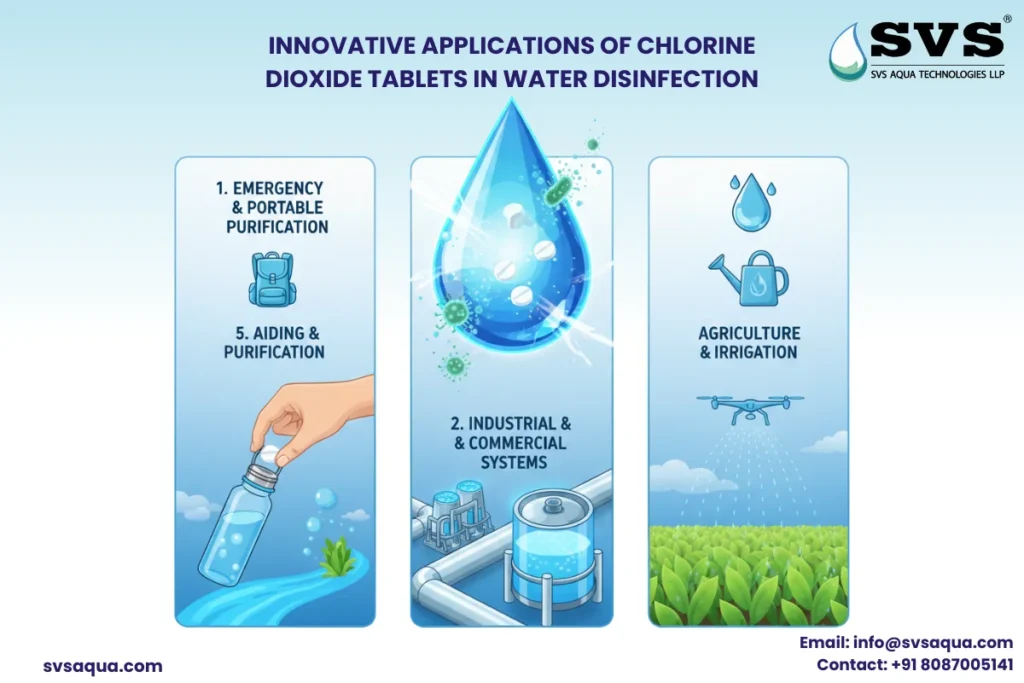

INNOVATIVE APPLICATIONS OF CHLORINE DIOXIDE TABLETS IN WATER DISINFECTION

Engage With Us

HOW CHLORINE DIOXIDE TABLETS IMPROVE WATER DISINFECTION EFFICIENCY

Water must be thoroughly disinfected for safety reasons as well as to maintain operations’ compliance and efficiency. Conventional techniques like UV or chlorine frequently fail to eradicate biofilms and resistant bacteria. This is where tablets of chlorine dioxide (ClO₂) offer a potent, secure, and efficient substitute.

Engage With Us

WHY CHLORINE DIOXIDE TABLETS ARE A BETTER CHOICE?

Chlorine dioxide eliminates dangerous chemical byproducts and targets a variety of pollutants, unlike bleach or UV therapy.

KEY BENEFITS OF CLO₂ TABLETS

- Wide Range Disinfection: Destroys bacteria resistant to chlorine as well as E. Coli and Legionella..

- Secure and Clean: Avoids the formation of harmful byproducts such as chloramines or THMs

- Economical: Better long-term return on investment, fewer system failures, and less maintenance.

- Simple to Use: It’s easy to measure, store, and transport tablets.

COMMON USE CASES ACROSS INDUSTRIES

- Food & Beverage: Maintains packaging and processing areas hygienic and legal.

- Healthcare: Ensures the safety of water in clinics and hospitals.

- Municipal Water: Guarantees the public has access to safe drinking water.

- Industrial Plants: Stops biofilm from growing in boilers, cooling towers, and wastewater systems.

HOW TO USE CHLORINE DIOXIDE TABLETS EFFECTIVELY

- Test the Water: Decide on the main pollutants and trouble locations.

- Select the Appropriate Tablet: Fit the dosage to the kind of system and water volume.

- Construct a Delivery Mechanism: Assure the safe and equitable distribution of ClO₂.

- Keep an eye on the results: Keep track of efficacy and modify dosage as necessary.

- Educate Your Staff: Ascertain appropriate handling and safety procedures.

When it comes to treating industrial water, chlorine dioxide pills are revolutionizing the field.

They are dependable, economical, and environmentally friendly.

For those in the food processing, medical, or water management industries, SVS Aqua offers reliable ClO₂ tablet solutions.

FAQ FOR CHLORINE DIOXIDE TABLETS IN WATER DISINFECTION

Chlorine dioxide tablets are pre-measured tablets that release chlorine dioxide (ClO₂) when dissolved in water. Once dissolved, the chlorine dioxide disinfects the water by killing bacteria, viruses, fungi, and other harmful microbes — making the water safe for drinking or other uses.

It usually takes 20–30 minutes for the tablet to dissolve and fully disinfect the water. For heavily contaminated water, you may need to wait a little longer as per instructions.

Yes. It helps prevent bacterial build-up in tanks and pipelines before water reaches your RO or filters.

No. They dissolve completely and do not leave visible residue. Water looks clear after treatment.

Chlorine dioxide works best in clear water. If your water is muddy, first filter out the dirt, then use the tablet for best results.