CASE STUDY- STEEL AUTHORITY OF INDIA LTD. (SAIL)

PROJECT ID :

| Company | SAIL - STEEL AUTHORITY OF INDIA |

|---|---|

| Location | India |

| Year | 2023 |

| Description | Drinking Water Plant |

| Goal | 1-NTU-Turbidity | 1-PPM-TSS | Recovery min 98% flow |

| Capacity | 380 m3/hr or 9 MLD |

| Water Source | Surface Water |

CHALLENGES :

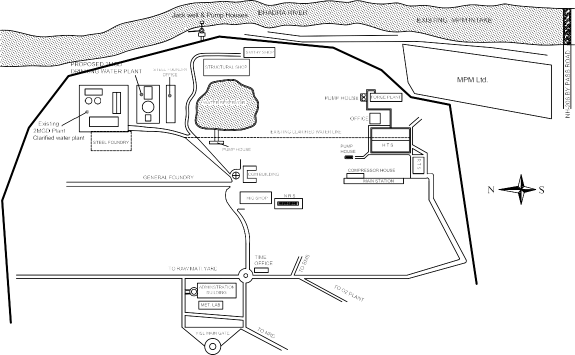

- High Turbidity and TSS in incoming water with frequent variations. 2. Space constraint at existing site.

- RGF – Rapid gravity filters are not feasible.

- The customer needed 100% Automation to avoid Manual operation for any operational errors.

- The backwash water system is of a limited size.

INSTALLED SYSTEM :

- Pre-fabricated MSEP structural plant in minimum space and civil work 2. No Air Scouring

- Scada system with 4 x 20 output with HMI and PLC panels for 100% Automation.

- 4. Automated backwash arrangement.

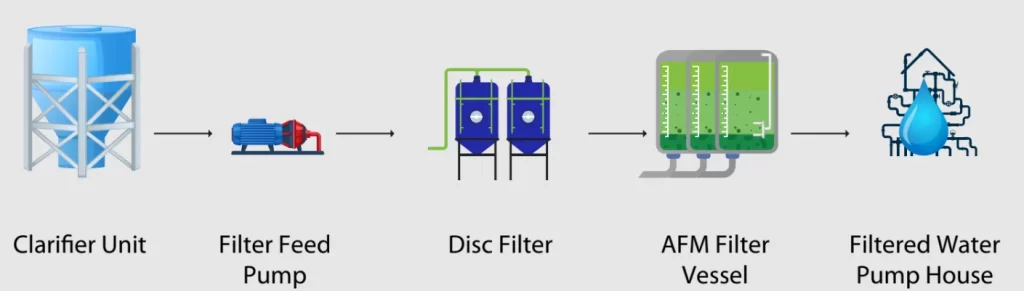

- Filtration scheme: Claried water is pumped to the AFM vessel through disc filters, Filtered water is pumped out for drinking purposes tank

- AFM Filtration plant area – 200m2

SYSTEM INTEGRATION AND PROJECT EXECUTION DONE BY YAHA WATER SYSTEM

PROCESS FLOW DIAGRAM

KEY FEATURES :

- Guaranteed outlet parameter with Turbidity up to 1 NTU and TSS- 1 ppm • Project Lead Time- 6 months (instead of 2 years)

- AFM media warranty- More than 10 years

- AFM media need not require replacement or regeneration

- 50% less space.

- Plant can be retrofitted in case of shifting or expansion eliminating complete obsoletion.

- Required negligible civil structure.